Critical Service Chemical Injection Regulator

Background

A leading operator was experiencing an issue with over-pressuring a chemical injection valve due to high ring main pressure that led to excessive differential pressure across the metering valve on a asphaltene inhibitor injection circuit, a key piece of equipment used on production platforms.

Solution

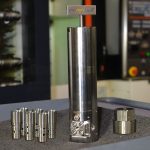

Proserv’s Gilmore Facility engineering team pro-actively designed a Chemical Injection Regulator as part of their Critical Service Valve product line knowing that this need existed in the drilling industry. The Critical Service Valve product line utilizes patented dual direction Key SealTM technology for the harshest environments in the oilfield, and pushes the envelope of higher pressures and temperatures on clean and corrosive, debris laden fluids. The new Chemical Injection Regulator reduces the pressure feeding into a chemical injection valve.

Some of the key strengths of the new Chemical Injection Regulator includes asphaltene, corrosion and scale inhibitor service. Metal to metal shear sealing technology provides near zero leakage and debris tolerance yielding a more robust and reliable solution. The regulator also maintains regulated pressure if supply is lost stemming from the dual direction sealing feature of the Key SealTM technology. A precision adjustment mechanism (1turn=70psi) for fine output pressure control delivers constant output pressure under flowing conditions. The Cv of approximately 0.2 at full open allows for smooth flow from GPD to GPM. And the modular no break hydraulic design with multiple output ranges at up to 8,500psi supply allows for rapid field adjustment.

Conclusion

The Critical Service Chemical Injection Regulator was installed on the operator’s chemical injection system and performed flawlessly extending the mean time between failure (MTBF) of the metering valve it was protecting by an order of magnitude to date. The realized MTBF improvement supported a return of significant cost savings and led the customer to issue a request of 23 units for all of their asphaltene inhibitor circuits on the Thunderhorse platform completing an order of $575k for the Proserv NSA team.

Benefits

- Asphaltene, corrosion and scale inhibitor service

- Metal to metal shear sealing technology provides zero leakage and debris tolerance

- Maintains regulated pressure if supply is lost

- Delivers constant output pressure under flowing conditions

- Allows for smooth flow from GPD to GPM

- Modular no-break hydraulic design with multiple output ranges at up to 8,500psi supply allows for rapid field adjustment

- Reduces maintenance servicing and downtime